About the project

The LSDisk® project includes the steps of research, development, design, production and marketing of filters for the sampling of organic and inorganic compounds in fluids.

LSDisk® originates from the requirements of several CNR researchers to have a reliable and innovative product for sampling semivolatile contaminants in environmental fluid matrices.

“Are you truly sampling properly from an analytical point of view?”

About the project

These systems are precisely pre-spiked, and the Sampling Standard remains consistent across time, starting from the addition of the solution to the final extraction process after the sampling step.

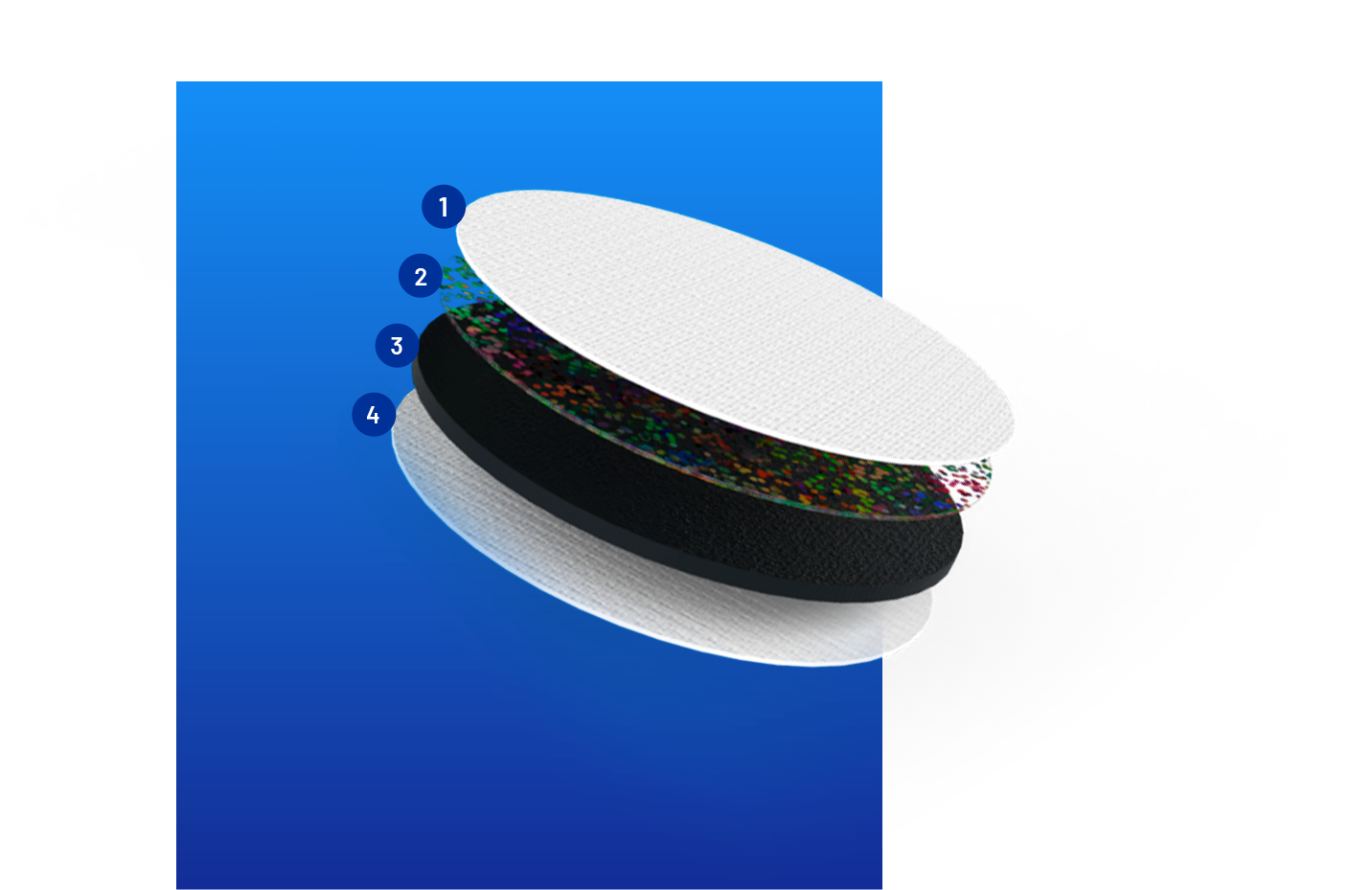

The device is a filtering / adsorbent system that is capable of retaining semi-volatile organic and inorganic compounds, ensuring the sampling / enrichment of the analytes from fluid matrices in the presence or absence of particulate matter. Said systems are accurately pre-spiked and the standard remains unaltered over the time, from the addition of the solution to the final extraction process after the sampling step.

LSDISK® HIGHLIGHTS

Economical advantages

Reduced amount of solid waste produced. LSDisk is an adsorbent disk capable of replacing multiple materials currently in use for the total quantitative determination of POPs.

LSDisk is a “ready-to-use” material: the step of preventive solvent washing of collection systems – necessary before each measurement campaign – is eliminated.

The stability of LSDisk over the time allows to save the time needed for the preparation of the standard solutions and the adsorbents to be used, enabling to be always ready for monitoring campaigns of unexpected events (e.g. fires).

LSDisk has an absolutely versatile structure, thanks to the chosen materials that adapt perfectly to different situations without losing all its advantages. It can be used in all the commercially available sampling systems, even in non-specified sequential instruments. Moreover the ACF adsorbent, thanks to its chemical and physical characteristics, allows the analysis of several classes of compounds.

Analytical advantages

LSDisk makes sampling feasible for anyone and in any situation: the mechanized addition of the Sampling Standard solution makes the operation consistent in time, with a high degree of accuracy of the results.

The repeatability of sampling will no longer depend on the operator who spikes the filter before sampling, nor on the technicians who prepare the working solutions in the laboratory. It will no longer be necessary to transport the Sampling Standard solution in the field, subjecting it to further variables that can lead to uncertainty in the concentration.

The operation of the field spike will be completely eliminated, so the sampling can be started quickly and in any weather condition (rain, snow, wind, extreme heat).

The stability of the spiked Sampling Standard onto the filter over the time (months) and at different temperatures, allows to have a high accuracy of the results even for long monitoring campaigns and during the transport of materials.

Chemical and physical hazard

LSDisk allows the reduction of the chemical and physical risk to which operators are exposed. The chance of having a product already cleaned and pre-spiked with the Sampling Standard reduces the exposure to chemical agents.

The contact of the operator with solvents and syringes remains confined to the safe laboratory environment for sample extraction and purification.

LSDisk allows the elimination of the transport of liquid chemicals (solvents and standards) during the sampling step and their handling in the absence of mechanical ventilation, reducing the inhalation hazard for the operator.

Experimental evidence

Sampling Standard Solution. Why is it so important?

For a sample to be considered valid, several standard reference methods require the addition of a Sampling Standard solution (SS) to the adsorbent medium prior to sampling, and the recovery of each congener must fall within a defined range.

When using the isotopic dilution technique, standard solutions containing isotopically labeled compounds are added before three different phases of the analysis: sampling, extraction and instrumental analysis.

The Sampling Standard’s role is to assess the possibility of analyte losses during the sampling phase.

The Sampling Standard’s recovery rates allow us to assess the efficiency, accuracy, and overall capabilities of the sampling device and of the analytical procedure.

The addition of the standard solution is apparently a simple procedure but it is critical in order to avoid errors during the analytical process, but its importance is sometimes underestimated, even though standard reference methods highlight it.

Addition of the standard

The standard addition is a critical step during the analysis and the spiking procedure is one of the most critical phases. According to standardized methods, the addition is performed directly on the sampling site on the QFF or PUF. This procedure reduces the possible losses of the standard due to its degradation or volatilization during transport, but on the other hand, it is subject to some potential drawbacks. The stability of the standard during the sampling campaign, the reproducibility of the operator, the subjective execution of the spiking between one operator and another, the atmospheric and environmental conditions in which the procedure is carried out should not be underestimated. Furthermore, on-site addition has proven to be a risky and time-consuming operation (labeled compounds are carcinogenic) in a planned and tight sampling campaign.

LSDisk gives the possibility to skip the tedious step of the spiking of the Sampling Standard Solution by increasing the reproducibility, no longer being subject to atmospheric events, nor linked to the operator’s ability, in total safety without handling solutions.

Resistance to temperature stress

Pre-adding the solution of the sampling standard on the adsorbent medium in the laboratory and transporting it to the field may apparently seem the solution to avoid many unexpected drawbacks.

However, it is necessary to take into account the storage temperature, which is one of the parameters that act on the volatilization process of the SS standard from the adsorbent medium.

LSDisk guarantees pre-spiked filtering devices that are able to maintain the Standard amount unaltered at up to 35°C, withstanding much more thermal stress than the normal adsorbent media commonly recommended by the ISO and EPA method. Studies have shown how LSDisk technology, compared to common sampling media, guarantees recovery of sampling standards that meet the methods and EPA up to 35 °C. Already at temperature (20 °C) LSDisk has a higher efficiency of 85% for PCDD/Fs and 77% for ambient PCB to retain the sampling Std.

Stability over time

The studies conducted for the development of LSDisk are aimed at solving the problems that POP analysis operators may encounter in a practical way. “How much volume can I sample with LSDisk without incurring in breakthrough?”

LSDisk has been tested to answer this question by not finding any significant differences in the recovery rates of the SS standards even after three months, and the rates are all within the requirements of the EPA and ISO reference methods.

It will no longer be necessary to be ready in advance for a monitoring campaign, you just need LSDisk.

No more losses of analytes and Sampling Standards

When the filter is spiked before a sampling campaign, a partial loss of the standard could occur due to the degradation of the sorbent medium through phenomena like exfoliation, abrasion, contact with the storage container, operator errors, and needle or tweezers piercing.

LSDisk was designed to protect the sampling standard from these types of errors as well. The outer casing was chosen to protect and ensure high impedance-free efficiency for sampling with low-value blanks.

with the claim of the priority of the Italian application n. 102020000019936 filed on 11 August 2020